CYX12 series pressure sensor

2020年5月17日

CYX20 series pressure sensor

2020年5月17日CYX19-32 series pressure sensor

CYX series oil injection core pressure sensors use internationally advanced high-stability, high-precision silicon pressure chips, adopt stress-optimized design sintering seat, through patch, gold wire bonding, diaphragm welding, high vacuum oil injection, pressure cycle stress relief, High temperature aging, temperature compensation and other processes. More than 30 years of research and production experience and process innovation have made the products have excellent…

1 Overview

CYX series oil injection core pressure sensors use internationally advanced high-stability, high-precision silicon pressure chips, adopt stress-optimized design sintering seat, through patch, gold wire bonding, diaphragm welding, high vacuum oil injection, pressure cycle stress relief, High temperature aging, temperature compensation and other processes. Thirty years of research and production experience and process innovation have made the products have excellent stability and excellent performance, and have been widely recognized by users.

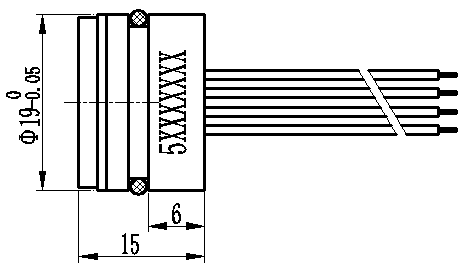

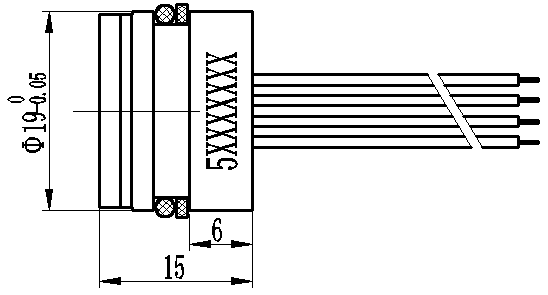

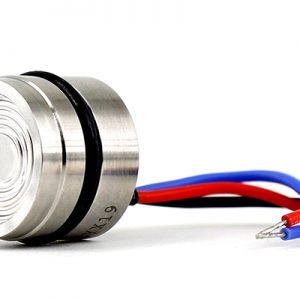

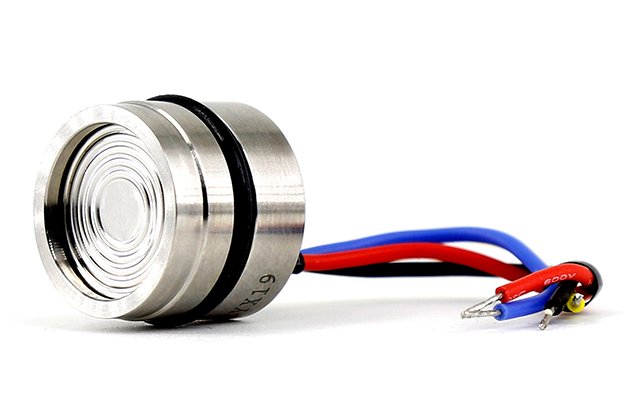

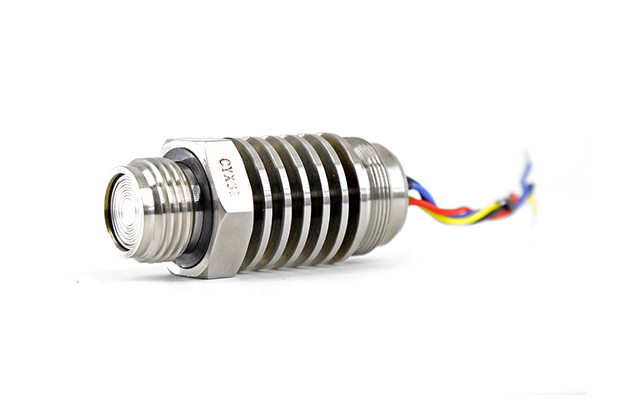

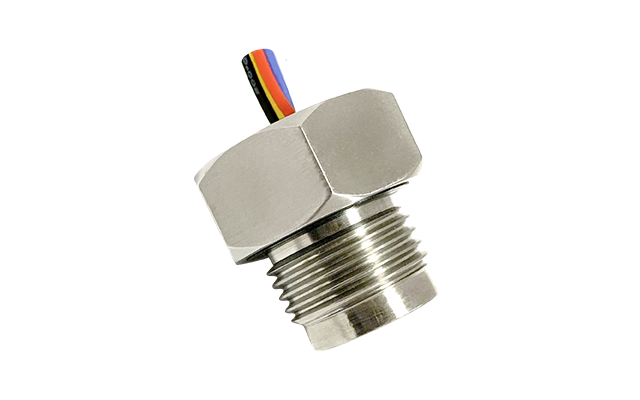

1.1 Universal type CYX19 oil injection core pressure sensor

The shape, assembly size and sealing method of the general-purpose product are consistent with the international mainstream similar products, and have good interchangeability. It is widely used in the pressure detection of 316L stainless steel and nitrile rubber or fluorine rubber compatible media.

1.2 Chlorine ion corrosion resistant CYX19 type oil injection core pressure sensor

The CYX19Ti oil injection core pressure sensor has the same appearance, assembly size and sealing form as the general-purpose CYX19 product. The new material titanium alloy is used for the structure, TC4 with high strength and good corrosion resistance is used for the shell, and TA1 is used for the diaphragm, which is more suitable for the medium pressure detection of strong corrosion of chloride ions such as seawater. Working in humid atmosphere and seawater medium, its corrosion resistance is far superior to stainless steel products, and it has strong resistance to pitting, acid corrosion and stress corrosion. It has resistance to alkali, chloride, chlorine organic materials, nitric acid, sulfuric acid, etc. Excellent corrosion resistance. Measuring range -100kPa~0kPa~10kPa…100MPa.

1.3 Gauge pressure type for measuring negative pressure CYX series oil injection core pressure sensor

Most types of oil injection core pressure sensors, such as general-purpose type, are produced by a special process of negative pressure, which can reliably complete the detection of lower than atmospheric pressure, and the range is arbitrarily selected between -100kPa and 3MPa.

2 Product features

● Measuring range 0kPa~10kPa…100MPa

● With gauge pressure G, absolute pressure A and sealed gauge pressure S

● Constant current/constant voltage power supply

●Isolated structure, suitable for a variety of fluid media

● Φ19mm standard OEM pressure oil injection core

● All 316L stainless steel

● Titanium structure optional, tantalum diaphragm customized

3 Main uses

● Industrial process control, liquid level measurement

● liquid level measurement,

● gas and liquid pressure measurement

● Pressure testing and calibration instruments

● Pressure switch and hydraulic system

● Refrigeration equipment and air-conditioning system

● Oil well monitoring, fire fighting, internet of things

● fire fighting, internet of things

4 Technical indicators

4.1 Electrical performance

● Power supply: ≤3.0mA; DC≤10V DC

● Electrical connection: 0.2mm2 four-color 100mm silicone rubber flexible wire

● Common mode voltage output: 50% (typical value) of current type input, 40% (typical value) of voltage type input

● Input impedance: 2.7kΩ~5kΩ

● Output impedance: 3.0kΩ~6kΩ

● Response time (10%~90%): <1ms

● Insulation resistance: 500MΩ/100V DC

● Allow overvoltage: 1.5 times full scale

4.2 Structural performance

● Diaphragm material: stainless steel 316L

● Titanium TA1 (CYX19Ti type)

● Shell material: stainless steel 316L

● Titanium TC4 (CYX19Ti type)

● Pressure tube material: stainless steel 316L

● Pin Lead: Gold-plated Kovar

● Sealing ring: Nitrile rubber, fluorine rubber (optional)

● Net weight: about 23g (general type, CYX19Ti type)

4.3 Environmental conditions

● Vibration: no change under 10gRMS, (20~2000) Hz

● Constant acceleration: 100g, 11ms

● Media compatibility: 316L and nitrile rubber (optional fluoroelastomer) liquid or gas

4.4 Benchmark conditions

● Medium temperature: (25±3)℃

● Ambient temperature: (25±3)℃

● Humidity: (50%±10%) RH

● Environmental pressure: (86~106) kPa

● Power supply: (1.5±0.0015) mA DC

4.5 Standard range sensitivity output and optional pressure form

|

Range |

full range |

pressure |

|

Range |

full range |

pressure |

|

0~10kPa |

(30~120) ±20 |

G |

0~3.5MPa |

(60~150) ±20 |

G/S/A |

|

|

0~35kPa |

(40~120) ±20 |

G/A |

0~6.0MPa |

(60~130) ±20 |

S |

|

|

0~70kPa |

(20~140) ±20 |

G/A |

0~10MPa |

(40~110) ±20 |

S |

|

|

0~100kPa |

(50~145) ±20 |

G/A |

0~25MPa |

(30~110) ±20 |

S |

|

|

0~200kPa |

(30~125) ±20 |

G/A |

0~40MPa |

(35-105) ±20 |

S |

|

|

0~400kPa |

(40~150) ±20 |

G/A |

0~60MPa |

(70~165) ±20 |

S |

|

|

0~1.0MPa |

(55~145) ±20 |

G/A |

0~100MPa |

(55~190) ±20 |

S |

|

|

0~2.0MPa |

(50~160) ±20 |

G/A |

4.6 Basic parameters

|

Parameters |

Typical value |

Maximum |

Single |

|

Full scale output |

100 |

250 |

mV |

|

Zero output |

±1 |

±2 |

mV |

|

Non-linear |

0.2 |

0.5 |

%FS |

|

Late |

0.05 |

0.08 |

%FS |

|

Repeatability |

0.05 |

0.08 |

%FS |

|

Input/output impedance |

2.6 |

5.0 |

kΩ |

|

Zero temperature drift Note 1 |

±0.4 |

±1.0 |

%FS,@25℃ |

|

Sensitivity temperature drift Note 2 |

±0.4 |

±1.0 |

%FS, @25℃ |

|

Long-term stability |

0.2 |

0.3 |

%FS/年 |

|

Excitation current |

1.5 (Maximum input voltage 10V) |

mA |

|

|

Insulation resistance |

500(100VDC) |

MΩ |

|

|

Compensation temperature Note 3 |

0~50;-10℃~70℃ |

℃ |

|

|

Operating temperature |

-40~+125 |

℃ |

|

|

storage temperature |

-40~+125 |

℃ |

|

|

Response time |

≤1 |

ms |

|

|

Housing and diaphragm materials |

316L stainless steel |

|

|

|

O-ring |

Fluorine rubber, nitrile rubber, silicone rubber |

|

|

|

Measuring medium |

Fluid compatible with 316L, nitrile rubber or fluoroelastomer or silicone rubber |

|

|

|

Life (25℃) |

>1×108 pressure cycle (80%FS) |

Times |

|

|

Filling medium |

Silicone oil |

|

|

|

Sealing ring |

Φ16×1.8mm (NBR or fluorinated rubber Note 4) |

|

|

|

Note 1, Note 2: The typical value of zero to 10 kPa temperature drift and sensitivity temperature drift is 0.5%FS@25℃, and the maximum value is 1.2%FS@25℃. Note 3: For 200kPa and below ranges, the compensation temperature is 0~50℃; for more than 200kPa, the compensation temperature is -10℃~70℃. Note 4: The temperature resistance range of fluororubber seals is -20℃~200℃, the low temperature performance is poor, when the temperature range is lower than -20℃, please verify the use. |

|||

5 Type selection structure

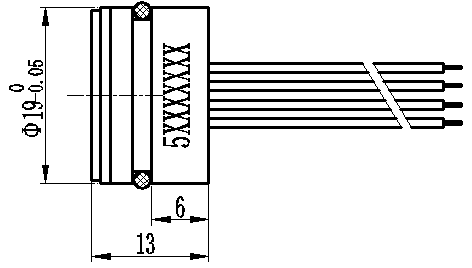

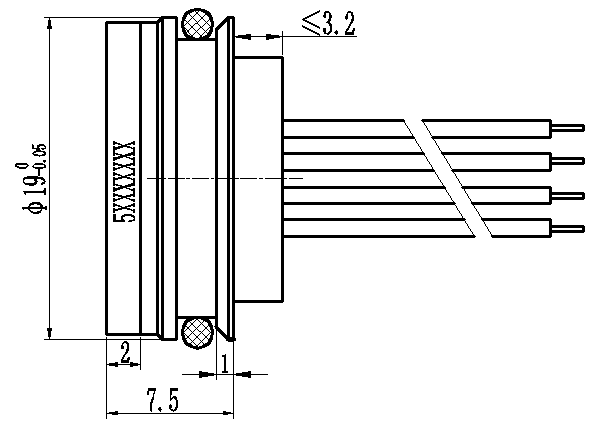

5.1 Core model selection model and outline drawing

|

Series |

Quantity |

Type |

Outline |

|

CYX19 |

-100kPa~10MPa |

CYX1901 |

|

|

CYX1901P |

|

||

|

25MPa~100MPa |

CYX1902 |

|

|

|

CYX32 |

-100kPa~3.5MPa |

CYX3201 |

|

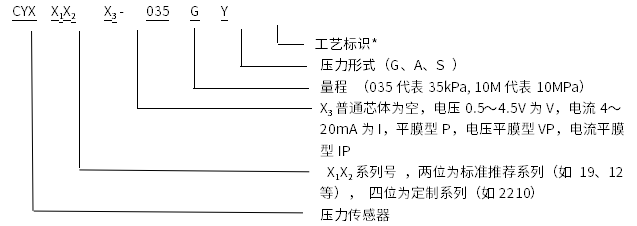

5.2 Selection guide

*Technology identification: f means general technology, Y means negative pressure technology.

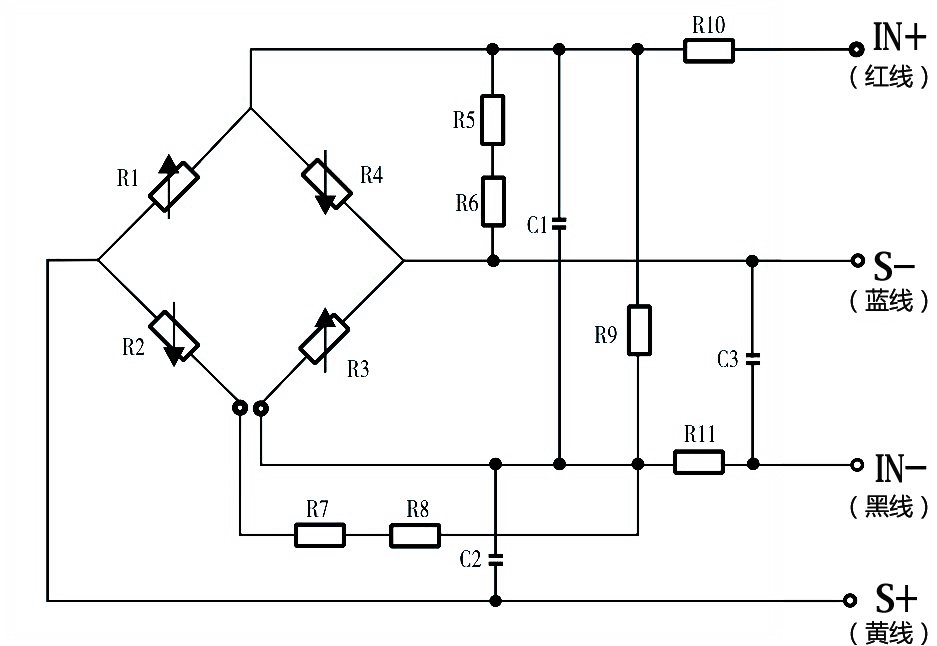

6 Schematic diagram and wiring

IN+(red line)-power supply positive IN-(black line)-power supply negative S+(yellow line)-output positive S-(blue line)-output negative

7 Application tips

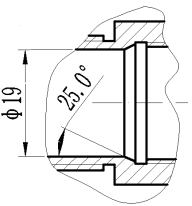

● The sealing method of the pressure core is recommended to use the “floating” sealing structure of the O-ring on the side wall to avoid the front end face compression and prevent affecting the stability of the pressure core.

● Pay attention to protect the front diaphragm of the pressure core and the compensation circuit board at the rear end, so as not to damage the performance of the pressure core or damage the core.

● The core cavity of the outer shell should be designed as shown in the tapered angle, easy to assemble the core, and prevent the right angle from scratching the sealing ring.

● When assembling, pay attention to the size of the core and the tolerance of the inner shell of the transmitter. It is recommended that the cavity be processed according to the core diameter of +0.02~+0.05 to achieve the required airtightness.

● When assembling, put it upright and press down evenly to prevent jamming or crushing the compensation piece.

● Do not press the metal diaphragm with your hands or hard objects to avoid damage to the core due to chip deformation or perforation.

● The core body pins should not be cut too short when wiring, the length is generally not less than 5mm, and the welding time is not more than 5 seconds.

● The vent pipe at the rear of the G-type core body should be kept open to the atmosphere; it is forbidden for water, water vapor or corrosive media to enter the reference cavity at the rear of the core body.

● Avoid dropping, bumping, etc., which will affect the stability of the product.

● If there is a change in the pin lead, the actual physical label of the core shall prevail.