CYB1800 series differential pressure transmitter

2021年1月18日

CYB1500 series clamp-type pressure transmitter

2021年1月22日1 Introduction

CYB3700 series flange pressure transmitters carefully select high-reliability silicon piezoresistance, ceramic capacitors, sapphire, sputtering film pressure sensors, etc. as the core components according to the application characteristics of different industries. After temperature compensation, digital circuit correction and signal conditioning, Output standard industrial signals. Each type of product has undergone careful design, component screening, process verification and curing, cyclic loading and aging, environmental simulation testing and other processes to ensure that each product is stable and reliable.

2 Features

◆on-site display, multiple output signal options

◆high stability, low drift

◆explosion-proof, IP66 protection

◆applicable to harsh environments such as pollution, humidity, flammability and explosion

3 Main uses

With its excellent accuracy and reliability, CYB3700 series flange pressure transmitters are widely used in many types of pressure measurement, especially in coal mine, oil field, chemical industry, civil explosion, environmental protection, medicine, water affairs, shipping and other industries. Brand pressure transmitters have been widely recognized by customers.

4 Technical index

|

range |

MPa |

-0.1MPa…0kPa~10kPa…10MPa |

||

|

pressure form |

G、A |

|||

|

accuracy level |

0.1(customized) |

0.25 |

0.5 |

|

|

nonlinearity (FS%) |

≤0.1 |

≤0.2 |

≤0.4 |

|

|

hysteresis, repeatability (FS%) |

≤0.05 |

≤0.05 |

≤0.1 |

|

|

zero point and sensitivity temperature drift (%FS/℃) |

≤0.015 |

≤0.03 |

≤0.05 |

|

|

long-term stability (%FS/year) |

≤0.1 |

≤0.2 |

≤0.5 |

|

|

operating Voltage (VDC) |

+10~+30( The calibration value is +24) |

|||

|

on site display |

4-bit LED or LCD |

|||

|

output signal |

4mA~20mA( Can superimpose HART protocol )、RS485( Can output 4mA~20mA signal at the same time )、 0~10V( Output range can be customized )、I2C |

|||

|

compensation temperature (℃) |

0~+50(≤200kPa),-10~60(>200kPa) |

|||

|

operating temperature(℃) |

-30~+60 |

|||

|

overload capacity (%) |

≤200 |

|||

|

load resistance (Ω) (4mA~20mA) |

R=(U-12)/0.02-RD Among them: U is the power supply voltage RD is the internal resistance of the cable |

|||

|

response time (10%~90%)ms |

≤1 |

|||

|

measuring medium |

Fluid compatible with 304, 316L or ceramic |

|||

|

diaphragm material |

316L、 ceramics |

|||

|

shell material |

304、 Aluminum alloy |

|||

|

interface |

304, 316L optional |

|||

|

explosion-proof grade |

Intrinsically safe :Ex d IIC T5 Gb |

|||

|

protection level |

IP65 |

|||

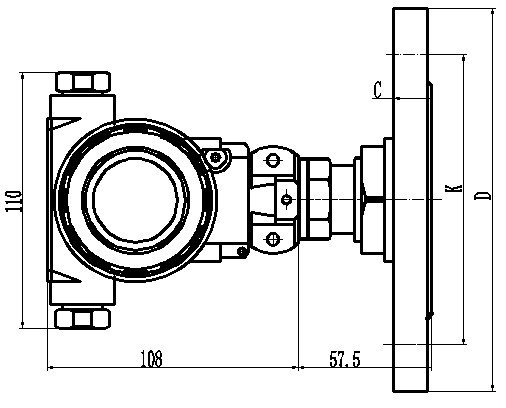

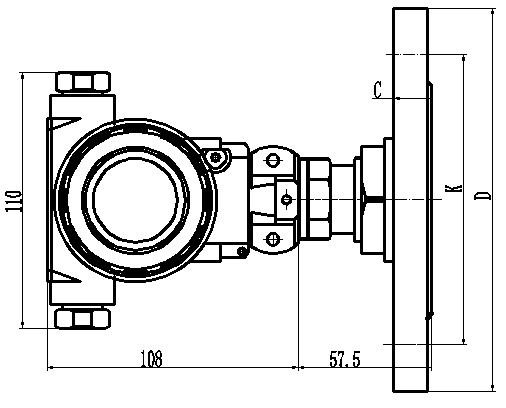

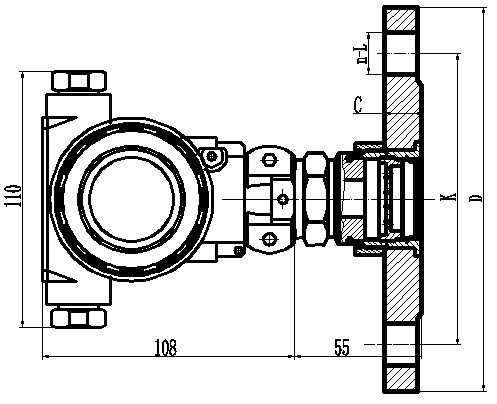

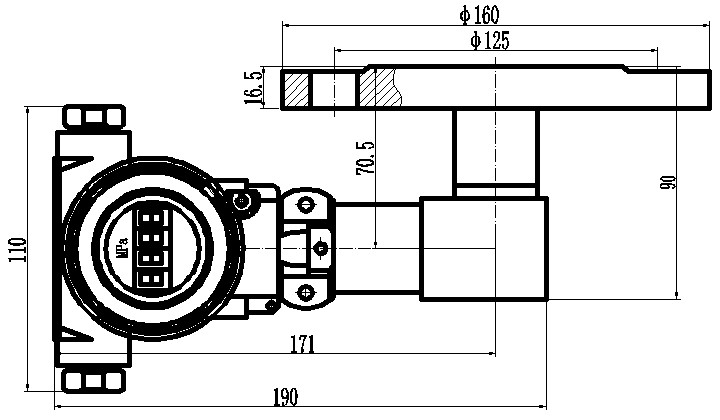

5 Transmitter size

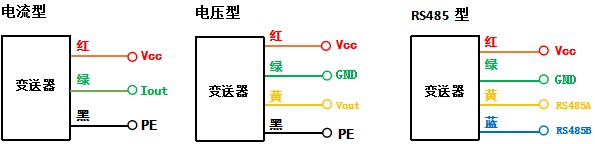

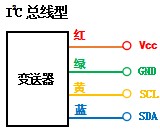

6 Electrical connections

6.1 Cable direct outle

6.2 Industrial terminal

7 Order guide

7.1 Model characteristics and appearance

|

model |

features |

pattern |

|

CYB3702 |

1、Welded transmitter meets the hygienic requirements of the pharmaceutical and food industries; 2、Optional range: -0.1MPa…0kPa~10kPa…10MPa;

|

|

|

CYB03703 |

1、Ceramic capacitor flange type pressure transmitter 2、Measuring medium temperature -40℃~80℃; 3、Suitable for non-corrosive medium to ceramics and stainless steel; 4、The pressure sensitive film is exposed, suitable for viscous media. |

|

|

CYB3704 |

1、Anti-corrosion type can be customized; 2、Customized on-site display; |

|

7.2 Selection guide

|

CYB37X3X4 |

Flange pressure transmitter |

|||||||||||||

|

|

Range |

Measuring range: -0.1MPa…0MPa~0.01MPa…10MPa |

||||||||||||

|

xxn |

The unit is kPa, the first two digits xx value is multiplied by the n square of 10, and n is the third digit value. |

|||||||||||||

|

|

|

Code name |

Pressure form |

|||||||||||

|

G |

Gauge |

|||||||||||||

|

A |

Absolute |

|||||||||||||

|

D |

Differential pressure |

|||||||||||||

|

S |

Sealed gauge pressure type |

|||||||||||||

|

|

|

Code name |

Supply voltage |

|||||||||||

|

U1 |

24VDC |

|||||||||||||

|

U2 |

12VDC |

|||||||||||||

|

U5 |

Other power supply methods |

|||||||||||||

|

|

|

Code name |

output signal |

|||||||||||

|

E1 |

4mA~20mADC |

|||||||||||||

|

V3 |

0VDC~10VDC |

|||||||||||||

|

V5 |

Other voltage output |

|||||||||||||

|

R4 |

RS485 Communication Interface |

|||||||||||||

|

H |

HART® Protocol communication |

|||||||||||||

|

Ⅱ |

I2C Protocol communication |

|||||||||||||

|

|

|

Mechanical interface |

||||||||||||

|

G¼ |

||||||||||||||

|

G½ |

||||||||||||||

|

G1 |

||||||||||||||

|

M20×1.5 |

||||||||||||||

|

Other( Direct label ) |

||||||||||||||

|

|

|

code |

Additional functions |

|||||||||||

|

M1 |

4-digit LCD digital display header |

|||||||||||||

|

M2 |

4-digit LED digital display header |

|||||||||||||

|

i |

Intrinsically safe explosion-proof type intrinsically safe type:Ex d IIC T5 Gb |

|||||||||||||

|

QT |

other functions |

|||||||||||||

|

|

|

|||||||||||||

|

CYB03702 [102] G U1 E1 G½ M1 Complete model specifications |

||||||||||||||

Ordering model CYB3702 [102] G U1 E1 G½M1 indicates that the model is CYX3702 shape product, measuring range 1MPa, gauge pressure, 24V power supply, 4~20mA output, G1/2 threaded connector, with 4-digit LCD display.

7.3 Recommended flange size

|

model |

size |

range |

|

DN50 |

K=110 D=140 C=14 |

0.6 MPa |

|

DN50 |

K=125 D=160 C=18 |

≥1.0 MPa |

|

DN25 |

K=75 D=100 C=12 |

0.6 MPa |

|

DN25 |

K=85 D=115 C=16 |

≥1.0 MPa |

|

Flange size can also be customized according to needs |

||

8 Precautions

8.1 The flange of CYB3702 and CYB373 products can be customized, and the flange size shall be specified when ordering.

8.2 When selecting anticorrosive CYB3704 products, pay attention to the compatibility of shell material and measuring medium.

8.3 When the product has the risk of being soaked or submerged, it must be explained when ordering.

8.4 When selecting strong corrosion protection products, the product shell and meter head shall be well protected, and these parts do not have strong corrosion resistance.